Frequently Asked Questions

Wood Questions

What kind of wood should I use?

Most of our plans use standard construction lumber like pine or fir. It's affordable, easy to work with, and easy to find. It's also rapidly renewing and biodegradable, so a great eco friendly choice!

Can I use hardwoods instead?

Yes—just keep in mind they're heavier, cost more, and can be tougher on tools and harder to join together and finish. I recommend not tackling a hardwood project until after you have built several softwood projects.

What if my boards are warped?

Choose the straightest boards at the store. You can often work around slight warps by cutting them into shorter pieces.

What wood should I use for outdoor furniture?

Use red-toned or pressure-treated 2x lumber for framing, and cedar or cedar fence pickets for the decking. Outdoor furniture should be built like a deck—your local home center can help recommend the right wood for your climate.

Will my wood move or warp after I build?

Potentially, especially in humid climates. Let your wood acclimate indoors before building. Once acclimated and kept in a stable environment, movement should be minimal. Remember, most houses are built using framing lumber - it's all about keeping moisture down indoors.

Cutting Questions

Do I need a miter saw?

A miter saw is great, creating fast, safe, and precise cuts, even for beginners. But most plans can be built with a circular saw and a straight edge. If using a circular saw to cut, take time to practice, and get good at making cuts, before cutting your project boards.

How do I get clean cuts with a circular saw?

Clamp your board, measure twice, cut slow, and use a sharp blade. This takes practice, so spend some time making cuts. I go through becoming proficient at freehand cutting in my course, it is worth taking if you want to master this skill.

Will the store cut my wood?

Yes—most stores will do rough cuts to help you transport your materials home. But from store to store, the quality of cuts could greatly vary.

Joinery Questions

What screws should I use?

We recommend star-head self tapping screws for framing, most common sizes are 2-1/2", 1-3/4". Pre-drill if close to the edge or you find your wood is splitting.

Do I have to use pocket holes?

Pocket holes are the cheapest, easiest and fastest way to do some joints - like edge to edge or a hidden fastener joint. There are other methods, but these can be time consuming and expensive. We recommend using pocket holes as indicated in plans for best results.

How do I keep things square?

Use a speed square and measure diagonals after each step. Always clamp joints before screwing to keep them tight and flush.

Finishing Questions

Stain or paint before or after building?

A quick sand before and a full finish after gives the best results. Pre-finish if you're doing two-tone or detailed finishes.

What type of finish?

Use oil-based or water-based stain. For paint, cabinet-grade latex or enamel works great. High use surfaces on indoor projects should get a coat of polyurethane, I recommend a Helsman or Spar or other flexible poly that won't crack or peel with wood movement. For exterior projects, use a finish suitable for exterior fences.

How to get a smooth finish?

Start with a well sanded project. Sand between coats (220 grit), wipe clean, and apply light coats with a foam brush or roller.

Plan Questions

Can I change the size?

Many people do, and that's the great thing about building your own furniture! But do keep in mind going bigger might mean more supports are required, and often plans are optimized for minimal material waste.

Are these beginner-friendly?

Yes—plans are written with simple tools and clear steps in mind, with every effort to make plans as simple as possible.

Can I sell what I build?

Absolutely! Just don’t resell or repost the plans themselves.

General Questions

What tools do I really need?

A drill, circular saw, tape measure, square, and a few clamps will get you through most projects.

Do I need a workshop?

Nope! A driveway or small patio is plenty to get started, just make sure you have a level place to work. If you find you are building several projects a year, creating a small workbench is a great way to store tools and have a dedicated workspace.

What if I mess up?

Wood filler, sanding, or flipping boards goes a long way. Mistakes are part of the process!

What can I do to make my projects look more professional?

Start with straight boards, make accurate cuts, clamp all joints, and line up everything neatly. Sand thoroughly, use a neutral finish, and apply it in light coats for a clean look.

I've never built anything before. Where should I start?

Start with a few smaller softwood projects to get hands-on experience. Or if you're tackling a big project, buy a little extra lumber and practice your cuts and joints first. If possible, work with someone who has a bit of experience.

Care & Maintenance

How long will my furniture last?

With good joinery and regular care, your DIY furniture can last for decades. I have pieces in my own home that are over 20 years old and still going strong! One of the best parts about DIY furniture is that it’s easy to repaint, refinish, or repair—so your projects can grow and adapt with you.

How should I care for outdoor furniture?

Lightly pressure wash or hose it down once or twice a year. Tighten screws and reapply finish as needed to protect it—just like a deck or fence. A little upkeep goes a long way in extending the life of your furniture.

How about indoor furniture?

Regularly dust or wipe with a damp cloth. If it starts to look worn, a light sanding and touch-up paint or stain can refresh it in no time. DIY pieces are meant to be durable and fixable—so don’t be afraid to give them some love now and then.

Want to Build with Confidence?

Check out my ebook: 12 Skills to Build Your Own Furniture

It walks you through the core skills every builder needs—measuring, cutting, joinery, and finishing—so you can build beautiful furniture that lasts.

Still Have Questions?

Email us anytime at [email protected] and we’ll be happy to help!

Comments

MI_Guest (not verified)

Wed, 06/06/2012 - 20:59

1 x 3 Sawhorse Table

I've been looking for permanent sawhorse plans and this has the perfect thing.

I may put a third one in the middle as I'm going to replacing an old (1962 kitchen table) that holds my plants during summer, on the porch. The shelves will be great to hold extra pots, soil and the like.

JenWoodhouse (not verified)

Sat, 07/14/2012 - 10:09

Whitney does it again! The

Whitney does it again! The girl doesn't cease to amaze me!

John@RemodelingBIBLE (not verified)

Mon, 07/16/2012 - 01:09

Superb!

Absolutely one of the nicest instructionals I've stumbled upon today.

Milca (not verified)

Tue, 07/17/2012 - 04:08

Perfect way to use that IKEA tabletop that was given to me!

I have an IKEA tabletop sitting in the basement that I didn't know what to do with. Its still good, but couldn't get myself to find a use for it nor throw it out. This will be great for a secondary worktable! Thanks for the plans.

Christy Panzarella (not verified)

Fri, 08/03/2012 - 02:00

Im hoping to one day go live

Im hoping to one day go live with whitney. Lol.

Patmcfadden (not verified)

Tue, 09/25/2012 - 05:41

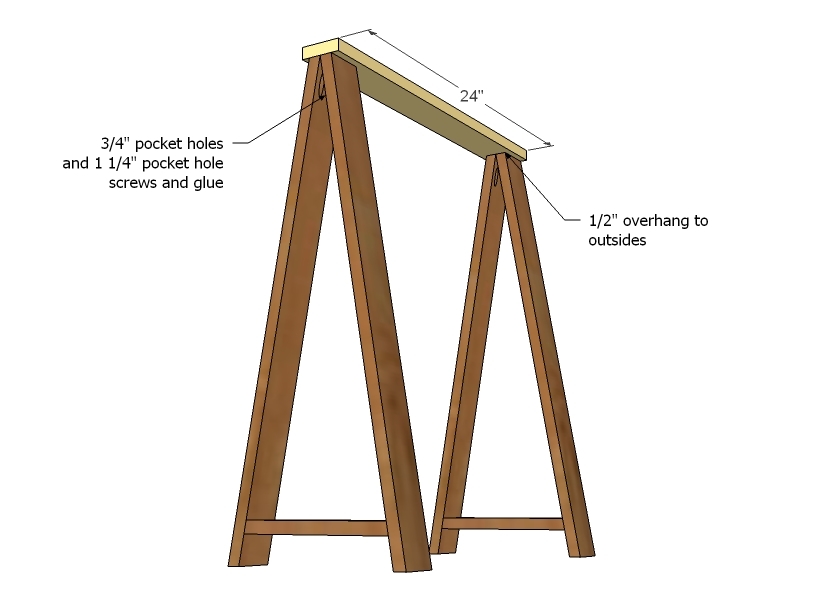

1x3 sawhorse desk

Any further instructions for step 4? Seems impossible to use Kreg jig and assemble at that point (get the drill and/or jig close enough). What am I missing? Thanks!

patmcfadden

Mon, 10/22/2012 - 19:02

Sawhorse desk

Can anyone provide further instruction on step 4? Using the Kreg jig to attach legs in this step seems really difficult. How do you handle that tight angle? What am I missing? Thanks.

ryan mcdermid (not verified)

Thu, 11/08/2012 - 06:09

Step 4 help

Kreg has a driver that is longer. Something like 5 or 6 inches. I didn't have any issues with the angle and I was worried as well. The other thing you can always do if your drill is too big to fit in there is to use a scew driver that accepts different scre heads and fit the kreg driver head in there and hand tighten.

Jake

Sun, 01/20/2013 - 19:24

FLOR Catalog

If anyone is interested I was looking through the latest FLOR Catalog (floor coverings) and on page 41 is the sawhorse desk.

Jake

Sun, 01/20/2013 - 19:28

Regarding Step 4

Personally I would just drill the PHs on the outside of the legs, fill them with vinyl spackling and then paint. You will never see them and you eliminate the hassle of trying to use a screwdriver with the square bit or a power drill in the tight space. Also if you stain the PH is really kind of artistic.

n0rse

Sun, 05/12/2013 - 22:19

Have spare 1x3s = this is a sawhorse?

What do y'all think? Would like two standard use sawhorses out of this. Thanks!

Jorge Velasquez

Mon, 10/14/2013 - 21:06

Can't do the beveled cuts!

I totally love this project, which is why right after reading it I went to the hardware store and bought myself a jigsaw and some lumber to start making it. However, after trying many times to do the beveled cuts for the legs (and just for the legs), I haven't been able to make the first straight cut! Any tips on how to do it? Is a jigsaw the right tool for the job? I really can't afford to buy a mittered saw just for this! Any sawhorse plans that don't require beveled cuts would be great too!

Kevin Wentworth

Thu, 08/11/2022 - 09:55

BEWARE STEP #4.....Pocket holes needed!

Would be helpful to see revised build instructions on Step#1 to include drilling the pocket holes needed at the tops of the legs during Step #4. This would make it far easier than trying to drill the holes after the bottom support and the bottom shelf are installed.